InFINITY MEETS REALITY

Ready-to-use 3D printing materials

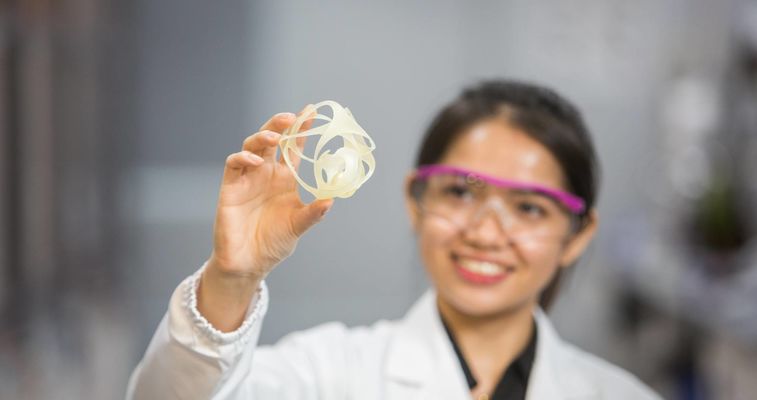

We boost polymer chemistry into ready-to-use 3D printing materials — nylon powders, elastomers, PEEK filaments, and specialized photopolymers — to unbound sustainable 3D printing at scale.

|

Product |

Class of material |

Technology |

|

Specialized polyamide 12 |

Powder Bed Fusion (SLS, HSS, MJF) |

|

|

High temperature polyamide 613 |

Powder Bed Fusion (SLS, HSS, MJF) |

|

|

Thermoplastic amide (elastomer) |

Powder Bed Fusion (SLS, HSS, MJF) |

|

|

Thermoplastic copolyester (elastomer) |

Powder Bed Fusion (SLS, HSS, MJF) |

|

|

Photopolymer resins (elastomer) |

Vat Polymerization (HL) |

|

|

Photopolymer resins (flame retardant) |

Vat Polymerization (DLP) |

|

|

Photopolymer resins (rigid) |

Vat Polymerization (SLA, DLP) |

|

|

Photopolymer resins (high strength) |

Vat Polymerization (SLA, DLP) |

|

|

Photopolymer resins (tough) |

Vat Polymerization (SLA, DLP) |

|

|

Polyether ether ketone (industrial) |

Material Extrusion (FFF, FDM) |

|

|

Bioresorbable polymer (implants) |

Material Extrusion (FFF) |

|

|

Bioresorbable polymer (implants) |

Powder Bed Fusion (SLS) |

|

|

Polyether ether ketone (implants) |

Material Extrusion (FFF) |

|

|

Polyether ether ketone (care) |

Material Extrusion (FFF) |

PEEK FILAMENTS

Evonik offers the industry’s most extensive portfolio of biomaterials used in the 3D printing of medical device parts designed for temporary and permanent body contact. New industrial grade filaments complete our portfolio.

NYLON POWDERS

Evonik is a world leader in the production of polymer powder materials, which have been used in 3D printing for over 20 years. The company offers a wide range of ready-to-use powders like PA 12, PA 613, TPA, or TPC suitable for common powder bed fusion technologies.

PHOTOPOLYMERS

With a total of seven new INFINAM® photopolymer materials for photo curing 3D printing technologies like SLA or DLP, Evonik has diversified the additive manufacturing material landscape in less than two years.

Polymer-based 3D printing materials

Materials used in 3D printing are just as important as the printers themselves. Polymers are still the most commonly used 3D printing materials; however, ceramics, metals or even sand are now available for 3D printing. The development of new 3D printing materials is expacted to help additive manufacturing expanding their application areas towards industrial 3D printing at scale.

According to a number of market reports, the global market for 3D printing materials is projected to growth at a CAGR of more than 25 percent between 2022-2027 time period. The market's growth is attributed to the factors such as easy in the development of customized products and reduction in manufacturing costs and process downtime.

Polymer-based 3D printing materials can be clustured into three type of materials depanding on main 3D printing technology of choice:

- Filaments for extrusion-based technologies like FDM or FFF

- Powders for powder bed fusion technologies like SLS, HSS or MJF

- Photopolymer resins for vat polymerization technologies like SLA, LCD or SLA

In order to develop specialized 3D printing materials that are suitable for particular 3D printing technology a joint effort and collaboration depth between material manufacturer like Evonik and technology providers and machine constructors is crucial. Evonik draws on almost three decades of experience in development and manufacturing polymer-based 3D printing materials in order to diversify the landscape of today's available high-performance materials for 3D printing.

High-performance materials to unbound 3D printing at scale

Thanks to the group's innovation strength, years of expertise in polymer chemistry and strong industry partner network, Evonik knows the right buttons to develop and manufacture materials and adjust process to a series capable solution.

We offer a wide range of nylon powders, elastomers, PEEK filaments and specialized photopolymers for industrial 3D printing. Our INFINAM® PA12 ready-to-use powders are considered the gold standard in powder bed fusion technologies. Furthermore, Evonik offers the industry's most extensive portfolio of 3D-printable biomaterials for medical technology, which can be used to manufacture medical device parts designed for temporary and permanent body contact.

In summary, Evonik's ready-to-use 3D printing materials are an excellent choice for anyone looking for high-quality, reliable, and versatile materials. Whether you are working on a complex engineering project or a simple prototype, Evonik has a solution that will meet your needs. With our excellent technical support and commitment to quality, you can be confident that you are using the best materials available on the market.

Supporting 3D printing market growth with customized rady-to-use materials

Plastics are durable, easily fusible, offer many possibilities with their properties, and are ideally suited for this cutting-edge technology. Evonik is a PIONEER for ready-to-use materials to unbound sustainable 3D printing at scale - having delivered the first polymer powders for additive manufacturing as early as 1996 and thus setting standards for plastic materials that are still valid today. With a variety of innovative high-performance 3D printing materials ranging from reinforced to flame-retardant and elastic materials, we are bringing the 3D printing industry a decisive step closer to series production.

Beside high-performance 3D printing materials, greater production volumes will require additive manufacturing to become faster. We work with many different companies and our Application Technology Centers accross the globe offer a showcase for the international 3D printer scene. In addition to machines from HP and 3D Systems, it features 3D printers from the German market leaders EOS and Voxeljet, the Swiss company Sintratec, or the Chinese manufacturer TPM.

Our deep understanding helps in the development of new 3D printing materials for the various printing processes. INFINAM® Polyamide 12 (PA12), used in countless applications, is often the basis for this. We can either work on the base polymer or with additives like flame retardants or glass particles, for example.

Regardless of how quickly additive production will gain an industrial foothold, Evonik is determined to consistently conquer every new application by manufacturing high performance 3D printing materials. That means observing the dynamics of the market, driving innovation, and contributing our own expertise in development of 3D printing materials in a targeted manner and at an early stage. Above all, Evonik sees cooperation along the value chain as a door-opener to one of the most exciting future markets for engineering plastics and high-performance polymers. This is where Infinity meets reality to unbound sustainable 3D printing at scale.

LET'S EXPLORE YOUR NEXT 3D APPLICATION TOGETHER!

The better we know you, the faster we can support you!

Podcast subscription

Listen to our exclusive podcast "Unbounding 3D printing at scale" by subscribing to our newsletter.