COVID-19

Evonik helps choirs

With the support of Evonik a new 3D printed vocal mask has been developed specifically for choirs and music classes allowing the user to sing unobstructed during the corona pandemic.

Customized vocal masks for choirs

With the ongoing COVID-19 pandemic, many industries have been impacted including choirs, music classes and concerts. Social distancing requirements have restricted gatherings that affect communities and people’s livelihoods. Public solutions often include wearing masks and hand sanitization to help reduce the spread of the virus. Most off the shelf masks are used for medical or respiratory safe environments. A new 3D printed vocal mask has been developed specifically for choirs and music classes allowing the user to sing unobstructed.

A music teacher from Austin, Texas, had reached out to a local 3D printing service provider Varia 3D, Inc. in hope of producing a mask, that would enable these pupils to sing and still keep them safe from a Covid-19 infection. “When I was contacted by him and his Design Engineer, I was excited to help them explore various 3D printing solutions,” said Brian Bauman, Founder of Varia 3D. Varia 3D originally produced parts in nylon but the initial results were not well received. “Although the mask frame was very thin, the nylon material was too rigid for this design,” Bauman explained. He continued, “We have been testing a new thermoplastic copolyester from Evonik and felt it might be a great solution for The Vocal Mask.” Everyone agreed and future prototypes were made in various thicknesses and sizes. After a short testing period, it was time to go to production.

Material of choice - Evonik's thermoplastic copolyester powder INFINAM® TPC

“We always educate our customers that 3D printing is not only used for prototyping but an economic solution for short-run production”, explains Baumann. The benefits of any tool-less production process are the ability to make design changes on the fly and provide on-demand customization as needed. “Varia 3D made a convincing argument that with 3D printing we would reduce our time to market and allow us to make changes based on early customer feedback,” music teacher David Angerman described. He continued, “Based on our prototyping costs, I was not sure we could get our price point low enough. We needed to order an initial 1000 units to get started with molding.”

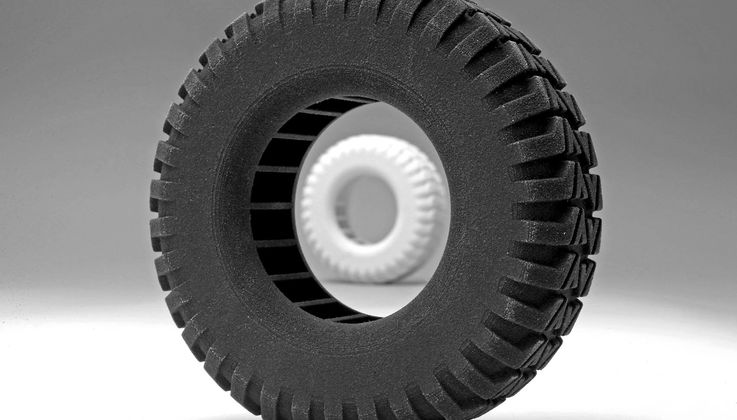

Varia 3D worked closely with Evonik to swiftly procure the required material. “Our new INFINAM® TPC powder appeared to be the perfect solution for this application”, said Abhi Bhat, who heads powder development at Evonik’s new 3D Printing Technology Center in Austin, TX. The material, which is available in white and black, is based on Structured Polymers’ technology for powder production that Evonik acquired in 2019. “With Evonik’s new thermoplastic copolyester material, we were able to check all the boxes for The Vocal Mask production,” said Baumann. He continued, “We needed the mask frame to be economically produced in a natural black flexible material with high compression and tear strength. We were able to meet this need eliminating risky tooling costs when launching a new product.”